Introduction

This guide will show how to fix a filament blob on the AnkerMake M5 3D printer. Blobs from a loose nozzle can cause clogs, poor print quality, or even damage the printer. My guide provides clear, simple steps to remove the blob and check the nozzle, helping users keep their printer working well without expensive repairs. This fix is designed to be easy for beginners to follow, making 3D printing smoother and less frustrating.

Tools

-

-

Press down on the black collar while pulling up on the PTFE tubing.

-

Using a 1.5mm hex wrench, remove the two screws on either side of the USB-C cable.

-

-

-

Plug the printer back in.

-

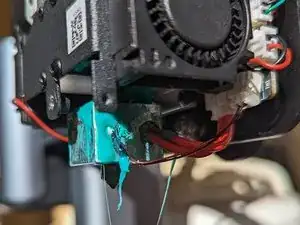

Power on the printer and heat the nozzle to 250°C for a few minutes to soften the blob. In many cases, the heat will melt off the blob if the extruder housing is removed.

-

-

-

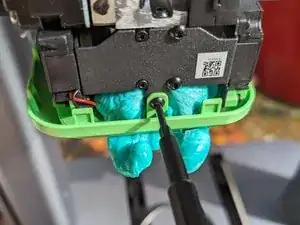

Once heated, turn off and unplug the printer. Carefully wiggle off the softened filament blob.

-

-

-

Now that the blob has been removed, it it time to clean the thermal sleeve.

-

The thermal sleeve may be embedded in the blob, and removing it might damage it. In that case install a new one.

-

-

-

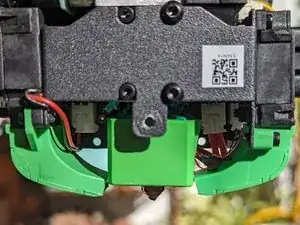

With the blob removed, inspect the nozzle for tightness and alignment. Adjust if necessary.

-

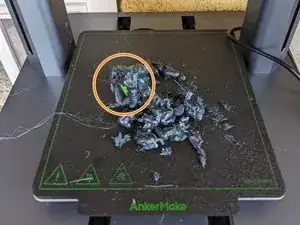

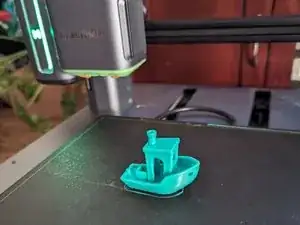

If the nozzle appears to be clear, create a test object to ensure that the nozzle is clean and in good condition.

-

-

-

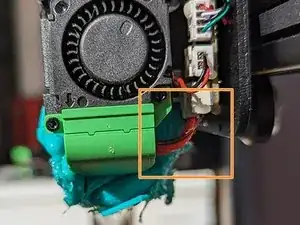

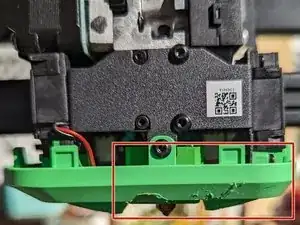

Some parts might have cosmetic damage.

-

Some parts might have functional damage. They can be replaced or reprinted, such as these orange fan ducts.

-